Services

Services

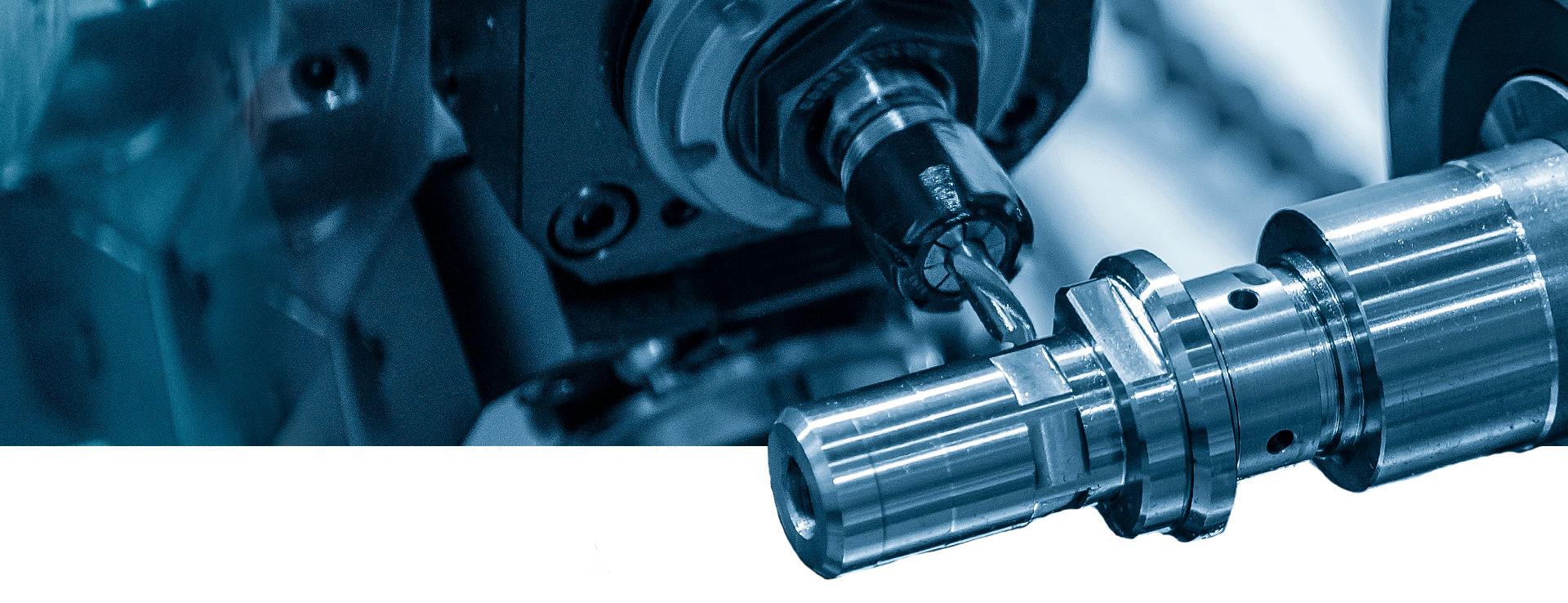

Anttrom provides high-precision machining of various materials.

Our combination of experience, applied knowledge and advanced technology ensures a high level of service at every stage: from processing of the part to packaging it and sending it to the customer.

Our focus are projects of high complexity, where accuracy to the micron is important.

Engineering and programming

Based on drawings and documentation from the customer, we carry out the engineering and programming of CNC machines, using Mastercam software, and offer effective CAD/CAM programming solutions.

CNC Machining Services

High-precision machining at the Anttrom plant is provided by multi-task turning and milling machines from manufacturers Bumotec and Okuma. These are high-tech pieces of CNC equipment that allow you to perform turning, milling and grinding operations from a single CNC machine.

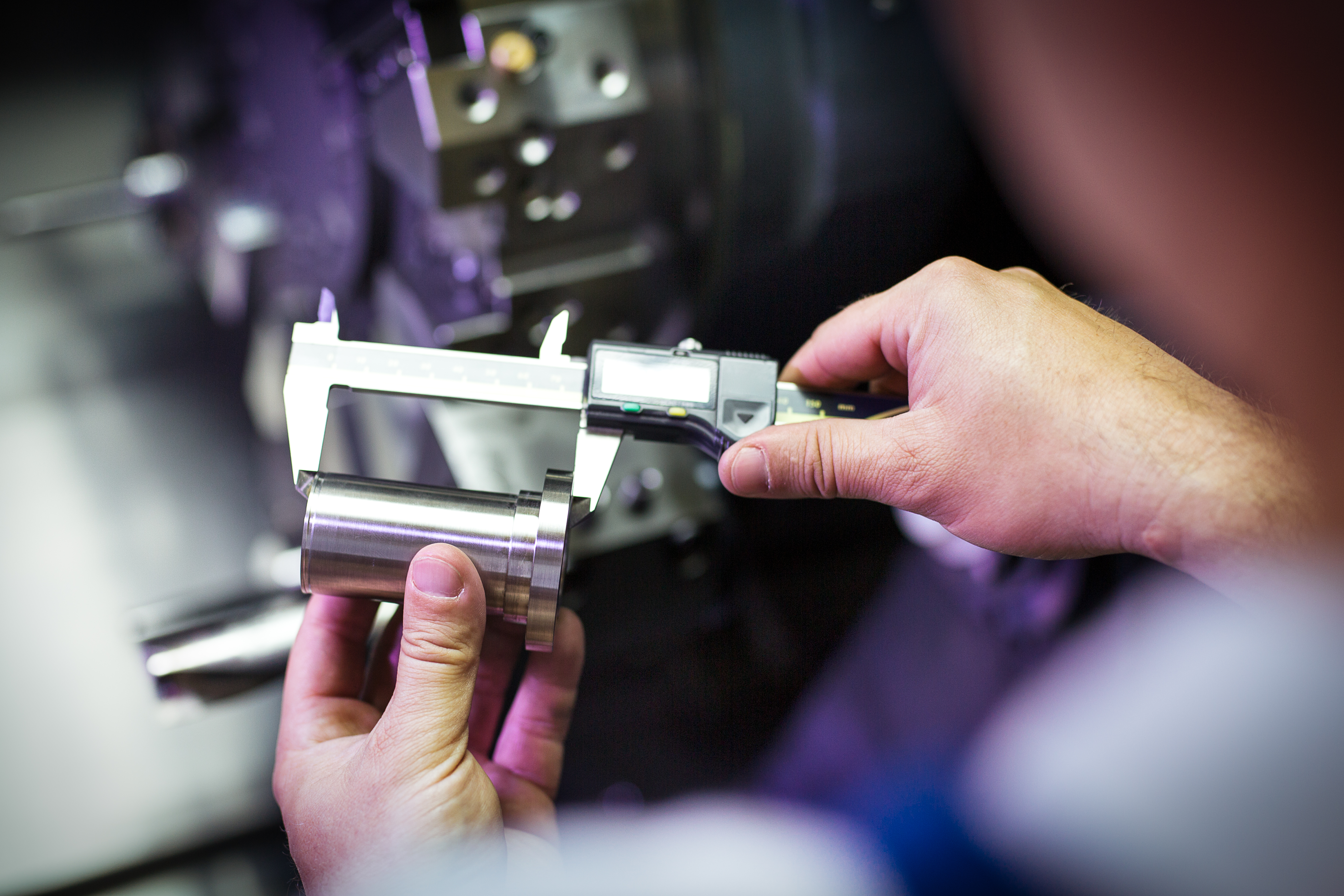

Precise measurements

High-precision parts require special attention during production. That’s why if you work in an industry where the price of a mistake could be a human life, you need to focus on quality control in production. One of the aspects of quality control is precise measurements.

Prototyping

In addition to mass production, we offer rapid prototyping – the creation and production of prototypes that will help you quickly test and bring your ideas and products to market.

Metal 3D printing

Recently, metal 3D printing has become a necessary extension to traditional production, and for that reason it has been called additive manufacturing. Certain parts are easier to make on a three-axis CNC machine, but products with complex geometric shapes can only be created using a 3D printer.

Quality control

Production at Anttrom is carried out in accordance with the requirements of quality control, as evidenced by certificates awarded to the plant, such as ISO 9001, ISO 14001, ISO 45001. Anttrom ensures that the company’s internal processes, whether production or management, meet the requirements of international quality standards.

Final processing and delivery

The final stage in the production or machine processing of parts is cleaning and processing. Once the parts are washed and cleaned, they are ready to be transported anywhere in the world by any type of transport.

Third party control in independent laboratories

If necessary, we can arrange geometric measurements and quality control in independent certified laboratories.

Anttrom provides high-precision machining of various materials.

Our combination of experience, applied knowledge and advanced technology ensures a high level of service at every stage: from processing of the part to packaging it and sending it to the customer.

Our focus are projects of high complexity, where accuracy to the micron is important.