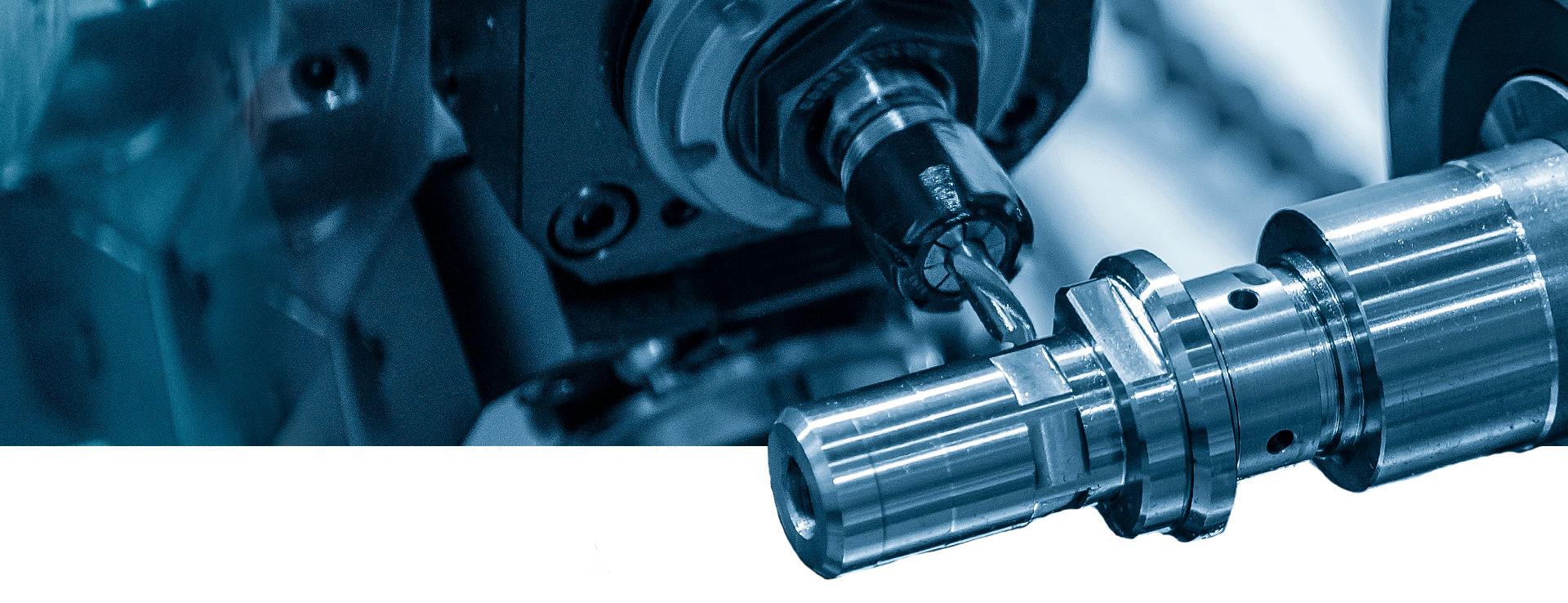

CNC Machining Services

Order custom CNC Machined parts online

30+ metal and plastic materials

30+ metal and plastic materials

ISO 9001 quality assured

ISO 9001 quality assured

Competitive prices

Competitive prices

Fast global delivery

Fast global delivery

When you need high production jobs, utilize the high precision machining option. Without a doubt, Anttrom has CNC machines that will guarantee quick processing. We also have the capacity to meet your production demands. Indeed, our quality and customer driven process will ensure you receive every order to specification.

Our Rapid CNC Machining Services

Why Come to Anttrom for Custom CNC Machining Services?

CNC machining is a challenging and tedious process, but with Anttrom’s help you can be the proud owner of your very own precision-made product. In addition, you’ll have a relationship with a company that produces thousands of part orders very quickly.

We have programming capabilities and automated equipment such as mills or lathes. Our machines run on preprogrammed instructions so that we make no mistakes when machining your needed product.

Production: If you need thousands of parts in a short period, then we can produce them.

In fact, using CNC equipment allows us to mass produce many parts in hours or minutes.

Productivity: Our machines multi-task by machining multiple angles of the part with multi-axis points.

Programmable: Programming our CNC machines provide precision and repeatability for the process and your parts. Therefore, the capability to replicate the production of a part through the CNC process provides consistency that you can trust for every piece.

Anttrom uses the latest high-tech CNC machines to ensure we meet your order specifications.

We guarantee quality in our products and services by maintaining certification for well-known international standards: ISO 9001, ISO 14001, ISO 45001.

We have a wide range of sizes that we process. Thus, your project can vary from 0.5 mm to 500 mm in diameter and up to 1500 mm in length.

Our response time is based on our customers’ needs. So, reach out to us at any time on any day of the year. Our team is dedicated to meeting your requests.

Find the best material, process, and surface finish with Anttrom. Reach out and our service personnel will discuss the most cost-effective options for your CNC Machining Project.

Receive your orders promptly no matter your location across Europe. In fact, our close proximately to the airport and seaport in Riga allows for easy shipping points.

CNC Machining Materials

Materials used for custom CNC machining will vary by application. The precision of our process is certainly able to handle many types of materials. The cost of certain types of material, such as plastic is less expensive to purchase. Depending on the use of the product a stronger material, such as metal, may need to be used. Thus, we machine a wide array of materials.

Wide Range of Surface Finishes for You

Choose multiple surface finishes for your machined parts. Add finishes to protect your custom CNC parts from harsher environments.

| As-Machined | We can hold machined surface roughness tolerance from 3.2 – 16 mm. This does not provide a protective barrier to environmental effects such as rusting. |

| Anodized | There are varying types of anodized. This is a colored finished and the chosen will define the type. |

| Powder Coat | This is more resistant to chipping than regular paint. The color is retained and the powder coat has much thicker layers than wet paints. |

| Passivation | This finish uses nitric or citric acid and removes free iron from the surface. It protects the surface with a chemical for functions as a rust preventative. |

| Titanium Anodize | This surface finish changes the oxide layer in a titanium surface using an electric current. If it is not treated after machining, it will create titanium dust when rubbed together. |

| Electropolishing | This provides a brighter finish for the machined surface. It is used to polish or deburr metal parts. |

| Electroless Nickel Plating | The use of electricity on metal surfaces to protect from corrosion or radiation. |

| Silver Plating | Put over a copper surface to protect it from oxidation (rusting). |

| Zinc Plating | Protects metal from rust even when scrapped because zinc does not rust. The product is dipped into molten zinc. |

Standard Tolerances for CNC Machining in Anttrom

Precision is key in many industries. If you have a product that must fit with or in another part to create a finished part, then machined tight tolerances are imperative. CNC machined product adheres to the measurements needed for processes after order completion. The tolerance that can be held with plastics and metals is all less than a sheet of paper.

| Limits for nominal size | Plastics (ISO 2768- m) | Metals (ISO 2768- f) |

| 0.5 mm* to 3 mm | +/- 0.1 mm | +/- 0.05 mm |

| 3 mm to 6 mm | +/- 0.1 mm | +/- 0.05 mm |

| 6 mm to 30 mm | +/- 0.2 mm | +/- 0.1 mm |

| 30 mm to 120 mm | +/- 0.3 mm | +/- 0.15 mm |

| 120 mm to 400 mm | +/- 0.5 mm | +/- 0.2 mm |

| 400 mm to 1000 mm | +/- 0.8 mm | +/- 0.3 mm |

| 1000 mm to 2000 mm | +/- 1.2 mm | +/- 0.5 mm |

| 2000 mm to 4000 mm | +/- 2.0 mm |

Precision Machining

CNC Machines have programmed precision. Anttrom defines the standard by which production and prototype parts must adhere to. If there are parts that you must meet tight tolerances, then we meet those expectations. CNC milling and turning machines refine a raw part to precise tolerances. The benefits are significant.

Add Value: We guarantee you will add value to the product. CNC precision machining adds value to your part by cutting costs and ensuring process efficiencies downstream.

Build trust: Precision machining is a process of repeatability. If you are providing for a manufacturer, then ensuring precision and the ability to control your output will build trust with your customers.

Opportunities for Development: There are so many options when you choose our CNC operations. With a wide range of high-precision equipment and experienced engineers, your opportunities for development and growth are endless.

Start with a prototype order. Continue the guarantee of precision with production orders.

Guarantee High Quality Machined Parts

Anttrom holds multiple international certifications. Our internal procedures also define the level of quality. We hold ourselves to the highest standards to ensure your high-quality CNC machined parts.

Our equipment allows for high-precision machining from one installation. Each machine is equipped with a probe to ensure quality control also is internally adjusted to the current situation on the machine.

Our team also provides documentation such as dimensional reports and first article submissions to validate the processing and data that parts meet all necessary specifications. We also decide the rework requirements and ensure that parts are made to specification.

Our Quality Promise:

• ISO 9001, ISO 14001, ISO 45001

• Material certifications

• Full report with every order

• Intermediate measurements on the machine

• Final inspection of parts by the quality control service

• Rework & refund policy

Quality Project Management and Support

Our well-defined and structured project management system is intertwined with the quality of products and services. We also provide support to ensure our customers have a streamlined supplier / customer relationship.

Anttrom: Trusted Across Multiple Industries

The customers and their respective industries characterize our CNC machining capabilities. We are always inspired by the wide array of industries that trust our CNC services. For example, the industries that we have experience with are:

Robotics

Robotics Aerospace and Defense

Aerospace and Defense Education

Education Energy

Energy Industrial equipment

Industrial equipment Medical and Dental

Medical and Dental Automotive

Automotive Electronics

Electronics

Заголовок

Описание

What is CNC Machining?

CNC machining is the use of computers in numerical control machines that manufacturers use to produce high-precision machined parts. Unlike the traditional numerical control, CNC machining promotes manual labor reduction that can foster faster-machined parts and enhance overall production. In fact, the CNC machining processes is a form of subtractive manufacturing that eases the production process by cutting products within necessary tolerances.

How Does CNC Machining Work?

CNC machining is when you use code to control the function of CNC mills machine, CNC turns machine, and CNC drills machine. As a result, you can make precise parts by using different types of machines like lathes, plasma-cutting, laser-cutting, jet or electric discharge machines.

Different commands will let you make things on the machine with a “G-code.” When the equipment starts, the raw material will become smaller parts. It continues to cut until meeting the formation of desired mechanical, medical, or industrial part specification is met.

CNC Machining FAQs

What is Your Experience with CNC Machining?

What Are the Advantages of CNC Machining Service?

How Much Does CNC Machining Cost?

Can CNC Machining be Used for Mass Production?